Emissions

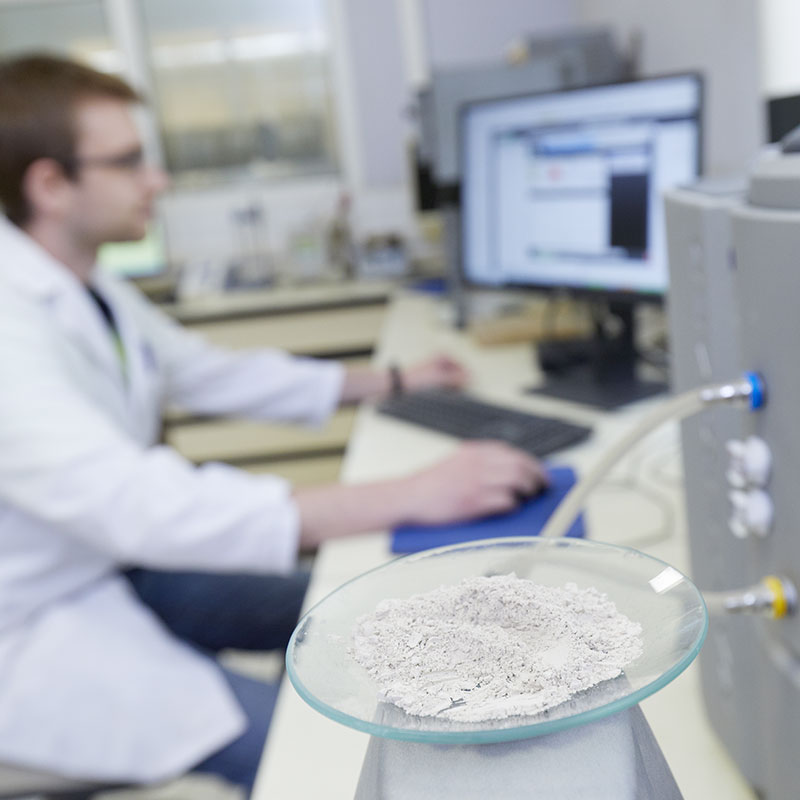

Advanced processes for the reduction and valorisation of air pollution in the exhaust gases from a calcined magnesite rotary kiln

Acronym: EMISSIONS

OBJECTIVE

The general objective of this project is to develop procedures, and associated technologies, to reduce the sulphur oxides (SOX), nitrogen oxides (NOX) and carbon dioxide (CO2) present in the exhaust gases from a calcined magnesite rotary kiln which, due to its particular characteristics (operating temperature range or high concentration of polluting gases), means that it is impossible to apply current technologies. This objective is complemented with the search for ways to valorise the emissions within the company’s production process, the by-products generated during the emission reduction processes, and the profitability and efficiency of the processes.

START date: 01/07/2011

END date: 31/12/2013